BlueCast X-One V2 MONOCHROMATIC LCD - AND DLP printers

Castable: Yes - Castability: Extreme

Compatible with: LCD AND DLP PRINTERS.

Before buy please check the printers compatibility on www.bluecast.info

INSTRUCTIONS AND PRINTERS COMPATIBILITY

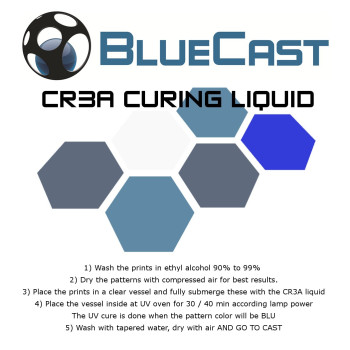

Washing mode and postcuring: Please check the Video tutorial.

UV care: Not needed

Shrinkage: Negligible

Color: Black - White after washing

Size: 500 gr

You might also like

ONE resin for ONE thousand applications

X-One V2 upgrades:

Same print profiles as version V1

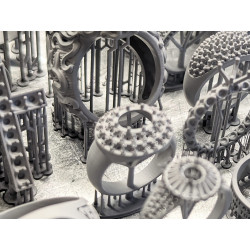

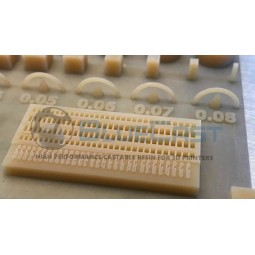

Improved resolution, especially for the new 12k printers. Better accuracy and reduced bleeding.

Enhanced printability, particularly for DLP technology (no need for additives).

Increased stability at low temperatures.

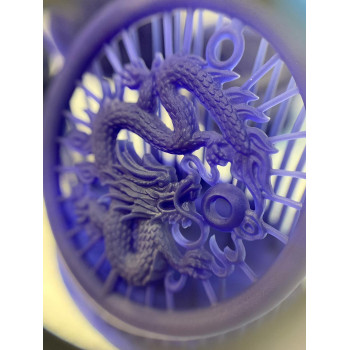

Improved meltability for micro-details and engravings.

– The first castable resin developed for the new LCD monochromatic generation and DLP printers.

– Perfect casting results with any kind of investments and burnout cycles. Low temperature burnout compatibility (even if we recommend 750°C last stage, everything is burned out at 680°C).

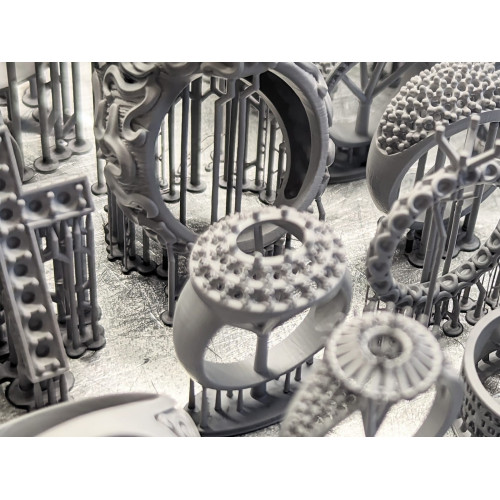

– Low temperature melting polymer ensures smooth surface finish and perfect lettering.

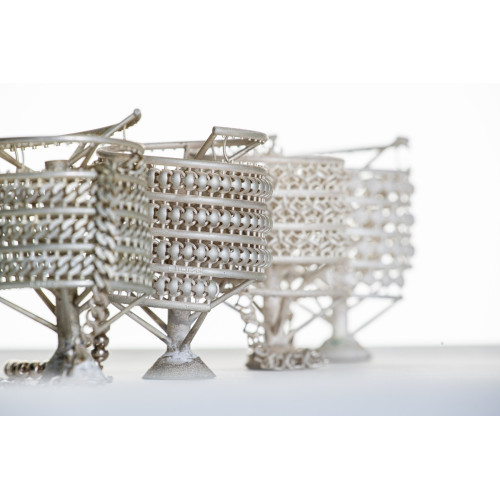

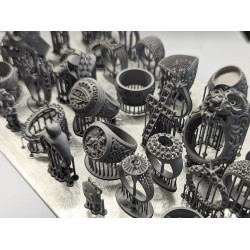

– Extreme accuracy and exceptional detail without shrinkage.

– No bleeding issue also on LCD machines.

– The first real meltable resin at low temperature.

– Excellent dimensional stability in time. No shrinkage (natural shrinkage will be compensated during print making polymer expand chemically).

– Low viscosity (easier to clean, easier to get back from patterns).

– Strong adhesion to platform (adhesion layers are exposure layers x4 or even x3), no need to primer.

– Toxic and carcinogenic component free, Low fumes emission during burnout. Very low VOC and negligible smell.

– Low fumes emission during burnout

– Finally, you can cast in any casting house/service every kind of pattern with text, engravings, micropavè etc.

– You can choice for chemical postcuring (longer washing in alcohol make a chemical reaction with X-One) or for traditional washing and UV oven postcuring. After chemical postcuring the color resin change from dark green to gray/white to permit you to check if the procedure was correct

You might also like