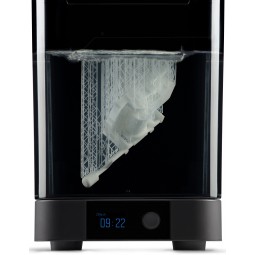

Print technology: SLA _ (Low Force Stereolithography)

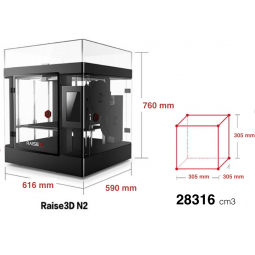

Print volume: 140x140x175 mm

Laser spot: 140 mn

Laser power: 250 mW

Resin heating: SI - Autorefill: SI

Resolution Z: 0.025 - 0.10 mm

X / Y positioning: 1.5 microns

Recommended minimum thickness of the surfaces:> 0.4 mm

Connectivity: WiFi, Eterneth, USB - Management software: Preform

Printable materials: Resins 405 nm

Formlabs Resins Availables: Standard, Flexible, Tought, Durable, High temp, Castable, Dental Model, SG for surgical templates

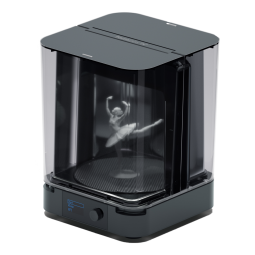

You might also like

Form Cure

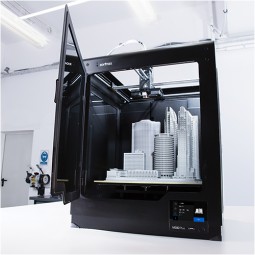

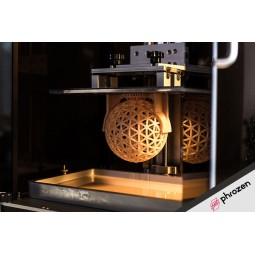

Flawless Prints, Every Time

Scale prototyping and production as your business grows with the Form 3, an affordable, industrial-quality 3D printer that consistently delivers.

The Next Generation of Industrial 3D Printing

With advanced Low Force Stereolithography (LFS)™ technology, Formlabs has completely re-engineered resin-based 3D printing to drastically reduce the forces of the print process.

Low Force Stereolithography (LFS)™ uses a flexible tank and linear illumination to deliver groundbreaking print quality and printer reliability.

Crisp, clean features:

The high-power-density laser is passed through a spatial filter to guarantee a clean laser spot.

Consistent printing:

A parabolic mirror ensures that the laser prints perpendicular to the build plane, ensuring uniform print quality across the entire build platform.

Faster than ever:

A high frequency galvanometer offers precise control and high speed.

You might also like