- 107 likes

- 34020 views

- jewelry, 3d printing, future, lost wax casting

Why 3D Printing?

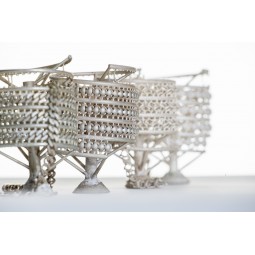

Traditional jewelry making methods like lost-wax casting are time-consuming and require a high level of skill. Imagine a jeweler meticulously hand-carving a wax model – it's an art form that takes years to master. But with 3D printing, jewelers can design intricate pieces digitally and print them with incredible precision. This not only saves time but also opens up a world of creative possibilities.

Benefits for Everyone

Independent jewelers can now produce unique, personalized pieces without the high costs and long lead times associated with traditional methods. Imagine offering your customers bespoke jewelry tailored to their exact preferences! And for larger manufacturers, 3D printing streamlines mass production, eliminating many of the manual steps involved in creating jewelry.

The BlueCast Advantage

Companies like BlueCast are leading the charge in this exciting new era. Their innovative castable resins are designed specifically for jewelry making, mimicking the properties of wax and even surpassing them in some cases. This allows jewelers to create high-quality pieces with exceptional detail.

A New Wave of Creativity

3D printing is empowering a new generation of jewelry designers. Startups are using this technology to compete with established brands, offering customized designs and pushing the boundaries of creativity. Imagine jewelry that appears large and bold yet feels incredibly light on the skin!

Embrace the Revolution

Whether you're an independent jeweler or a large manufacturer, 3D printing offers a world of opportunities. BlueCast, with its expertise and high-quality materials, is the perfect partner to help you navigate this exciting new landscape.

Ready to explore the potential of 3D printing for your jewelry business? Contact BlueCast today!